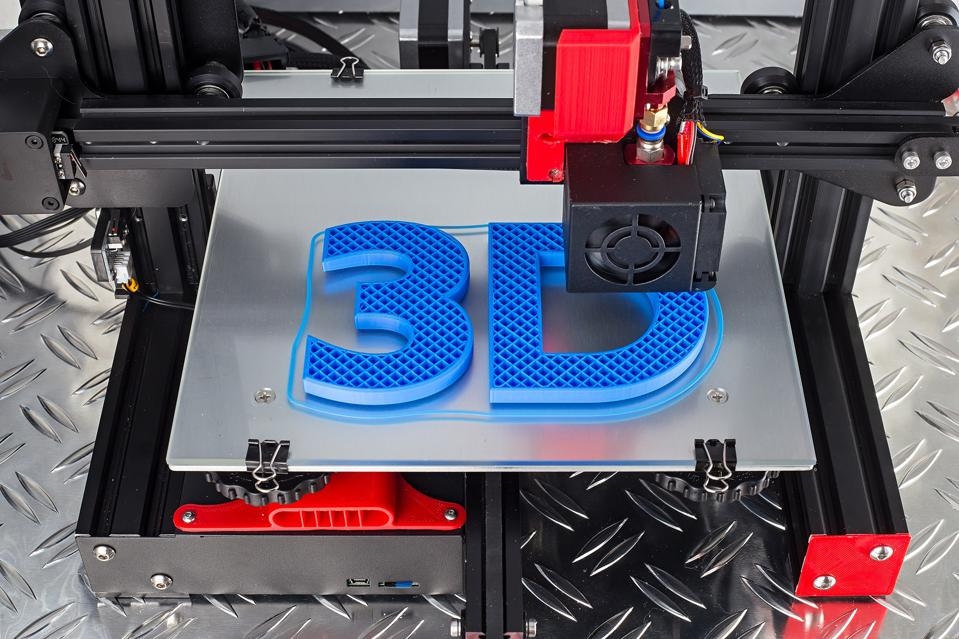

Have you looked at some products you use every day and wonder how they were formed? Different products are made of many shapes and designs that are so attractive and they can fit your needs very well. These designs are made through various processes such as Injection molding, CNC is the machining and 3D printing. In every step of production, you need the prototyping stage where you have some injection molded prototype, CNC machining prototype among others. 3D printing has remained standing out in the process of production. We will focus on the types of 3D printing machines and you will be able to understand which you prefer for your design.

FDM Printers

FDM stands for Fused deposition modelling or you may have heard of (FFF) fused filament fabrication? This is the same printing machine. FDM is used in the initial stages of product development mainly used in the production of medical designs.

This is a brief way on how an FDM printer works

Maybe you have heard the term, CAD? This is the initial stage of FDM printing. CD means Computerised Design. This is a model that is created with the help of the computer. This model proceeds to be sliced into various layers. At this point, the plastic filament is heated up by the FDM printer to the molten state. This printer extrudes the molten material in layers that build up to form the 3D object.

Materials used

Most of the materials used in this process are readily available plastics such as ABS (Acrylonitrile Butadiene Styrene) This is a readily available plastic that easily saves on cost.

PLA (Polylactic acid) is also a great substance that works best with FDM printers.

Pros of FDM printers

FDM 3D printers are affordable and readily available in the market. This is because they are mostly preferred for their ease of use and gives you a fast idea about your prototype. However, there are cons too. These printers are not best preferred for perfect production because they do not fulfil 100% perfection.

SLA 3D Printing

This is one of the oldest 3D printing machines that have been able to remain in the marke5 since the 1980s.

Let us interrogate how the SLA printing machine works

This printing machine uses the laser to act on the resin hardening the plastic through the process of photopolymerization.

Why does SLA standout more than FDM

SLA 3D printers produce high accurate features than FDM, the finishing of SLA 3D printing is super. You will always enjoy the outcome of the SLA printing machine. SLA also produces various products from thermal, mechanical and optical. These products will be able to meet engineering standards hence will be the best versions you can ever use.

The use of light for SLA printers makes it stand out in the printing process compares to FDM which uses heat. This is because the use of heat is subject to thermal expansion and contraction making FDM vulnerable hence less preferred.

The bond made between the layers of SLA is more strong compared to those made by the FDM printing machine.